PRODUCT- MoS2 Powder -

MoS2 Powder (Molybdenum disulfide powder)

Molybdenum disulfide (MoS2) is grayish black mineral composed of one molybdenum atom (Mo) and two sulfur atoms (S) in layers through the natural sulfurization of metal molybdenum underground.

MoS2 molecule is extremely small of 6.26Å, whose particle (0.4μm) has multiple layers (600-700 molecule layers).

These layers are easy to come off and each of them has a strong bond,which make the characteristics of lubricant agent.

Molybdenum disulfide has the following advantages:

- 1) It is soft (Mohs hardness 1) in spite of being a mineral, has fine particles (from 0.4μm) and is easily attached to a metal surface.

- 2) It is excellent particularly in terms of cold and heat resistance (-180 to 450℃), pressure and load resistance (2,842 MPa), and wear resistance (μ=0.03).

- 3) It is chemically stable and does not adversely affect other mixtures (fats, resin, rubber, sintered metal, etc.).

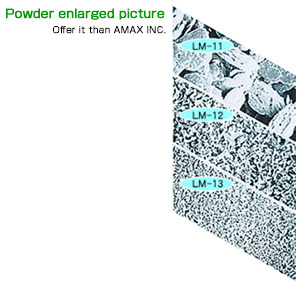

| Product number | LM-11 | LM-12 | LM-13 |

|---|---|---|---|

| Product name | Z Powder | NeO Z Powder | SM Powder |

| Properties |

|

|

|

| PV value (MPa・m/sec) | 92 | ||

| Heatproof temperature (℃) | -180 - 450℃ In inert gas 1,100℃ | ||

| Withstand load (MPa) | 2,842 | ||

| Coefficient of friction (μ) | 0.03 | ||

Molybdenum disulfide having such a property is used as a compound raw material or a compound material.

The followings are other application examples of Molybdenum disulfide:

- 1) It is added to oils or greases to exhibit lubricity.

- 2) It is used as a coating material for surface treatment of metal components for which lubricity is required.

- 3) It is added to plastic to be a material for various components.